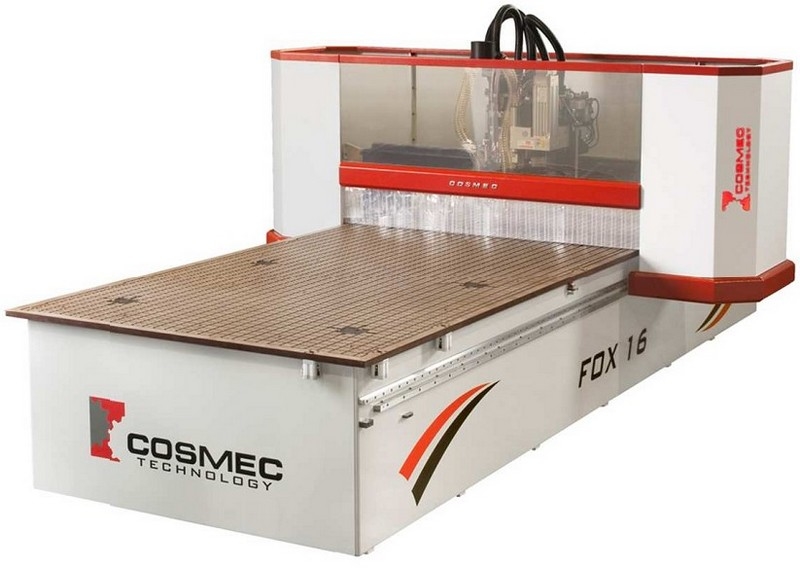

FOX 16 S

- Add feedback:

- Availability: Exists (1 szt.)

FOX 16 S CNC machining center

Use the form below to ask about the price and product details

FOX 16 S

CNC machining center with a fixed work table and a movable work carriage of the head with three CNC axes, suitable for processing wood, plywood, MDF, plastics and aluminum, composite boards such as alucobond or fiber cement with the use of appropriate options and tools.

CONSTRUCTION

Thanks to the gantry structure of the machine and the fixed work table, the maximum available space can be used and the travels are even.

The workpieces are always fixed to the table because the movements along the three axes X, Y and Z are guided by the carriage of the traverse and the work head.

This solution allows the operator to use the automatic unloading / loading system, and thus optimize the treatment with the shuttle mode

MACHINE BASE

The cradle and head traverse are made of an electrically welded steel structure that is standardized and properly ribbed for maximum rigidity and long service life.

SHIFTS

In the X and Y axes, the movement takes place in a rack system, with a drive on three precise gears.

Z axis movement is achieved by means of highly precise backlash-free ball screw drives for the highest reliability and precision.

The movement of the X axis takes place in the "gantry" system, which consists of 2 drive motors, one on each side of the base frame.

All shifts are carried out on linear guides with a prismatic rail equipped with high-precision carriages with recirculating spikes.

TECHNICAL DATA

X axis rapid speed: 24m / min

Y axis rapid speed: 24m / min

Z axis rapid speed: 12m / min

Vector speeds 55m / min

X-axis travel: 3000 mm

Y axis travel: 1600 mm

Max. panel transition thickness: 200 mm

Voltage: 380V, 50HZ, 3 Phase. + GND

ACCURACY

The positioning accuracy is guaranteed by the concentric rotary encoder with the possibility of setting the linear resolution + / - 0.005 mm and the angular resolution + / - 0019 °

PROTECTION SYSTEMS

The standard machine has a fast traverse feed of 24 m / min, therefore, in accordance with the requirements of the CE directive, it does not require special safeguards. For machines with a fast feed of 40 m / min, sensitive bumpers are installed, for higher speeds, mats and a protection circuit are installed.

WORKTABLE

The sandwich worktable is made of bakelite.

The work table is checked from a distance of 50 mm and is equipped with rectangular channels to limit the clamping area in relation to the dimensions of the workpiece. The operating area is divided into two sectors and allows machining on one of them to ensure complete transparency of loading / unloading operations in relation to machining, or over the entire surface

REFERENCE BUMPERS

2 sets, each with 3 buffers, located 1 on the left side, 1 on the right side and 4 on the front. The bumpers enable the correct rectangular positioning of the panel ensuring the correct reference to the mechanical zero.

VACUUM SYSTEM

The vacuum pump unit controls the loading / unloading operations of the shuttle for both table halves.

The table is equipped with vacuum switches that allow monitoring the pressure level reached in each plane and half of the table and, consequently, the correct clamping of the pieces of the workpiece. Vacuum unit pump with a capacity of 100 m3 / h, controlled by a 3 kW three-phase induction motor.

10 KW electrospindle with ISO 30 clamping with automatic tool change.

10 kW electrospindles with air cooling system. ISO 30 tool adapter with quick clamping system

The high torque fixed winding electrospindle enables machining that requires high torque, even at low speeds.

Technical data:

- 10 kW (13.5 hp) from 12,000 to 15,000 rpm for S1 operation

- 12 kW (16.3 hp) from 12,000 to 15,000 rpm for S6 operation

- Ceramic bearings

- Right and left rotation direction

- Programmable CNC rotation speed from 1000 to 24000 revolutions per minute

10-POSITION TOOL MAGAZINE

Linear tool magazine for ISO 30 / HSK F64 chucks with a magazine for 10 tools. The magazine is at the end of the X-axis stroke

Max. tool diameter mm 120 mm

Max. tool length mm 150 mm

Max tool weight 3 kg

Maximum total weight of 30 kg

JETS VACUUM

The number of suction holes is variable in the ratio of 2 pcs for each meter of the X axis.

ELECTRICITY

The cabinet is built in accordance with CE standards with an external voltage switch installed. The cabinet houses the CNC axis drives as well as all the power parts of the machine LUBRICATION SYSTEM

The machining center is equipped with a central manual lubrication system with nipples.

NUMERICAL CONTROL

The machining center is equipped with numerical control which includes all functions for proper management of axis enders It includes the OSAI CNC system on 36 controlled axes, open to all kinds of software.

MACHINE SETTINGS

Has the rail is equipped with a mobile console containing a monitor, keyboard and mouse containing the main operational functions of the machine, so as to be close to the machining site.

OPERATOR INTERFACE

The interface related to the control allows you to work directly on the CN or, alternatively, from a PC. Thanks to dedicated software, it allows you to work with the Windows platform.

The operator interface, the controller and the electronic part for controlling the machine are installed in a control cabinet mounted on rotating wheels. This system guarantees the operator the most suitable position for his job.

Vacuum system with a pump with a capacity of 250 m3 / h

The vacuum system is the most developed system in all its components and has the latest generation vacuum pump installed with a capacity of 250 m3 / h instead of 90 m3 / h. The vacuum pump unit controls both table halves for the swinging load / unload mode.

It is equipped with vacuum switches that allow you to monitor the level reached in each half of the table and, consequently, secure clamping of the workpieces.

Correctly sized solenoid valves ensure proper connection to the pump.

The 250 m3 / h pump is controlled by a 5.5 kW three-phase induction motor.

TOOL HOLDER

ISO 30 or HSK F63 with collet. Clamping diameter to be defined when ordering.

ASPAN SE

ASPAN SE is software from the ASPAN family. By using simple commands, it allows you to design workpieces quickly and easily (CAD environment), and then generate the necessary optimized machine programs (in the CAM environment).

1) CAD:

- General drawing commands (line, arc, circle, polyline, ...)

- Data unit setting commands (depth, diameter, ...)

- Unit commands modification commands (delete, move, copy, rotate, ...)

- Basic commands for managing paths (join, cut, cut, extend, ...) - Parameter functions (limited functionality, not all parametric formulas are available in Aspan SE version)

- DXF Import / Export (point, line, arc, circle, polyline, ellipse) Management of vacuum clamps

2) CAM:

- Tool management (tool length and diameter, speed of work, ...)

- Automatic tool assignment

- Manual assignment to holes

- Manual assignment to milling

- Assignment of an in / out path to a tangent line, arc tangent, ramp in Z, ...)

- Multi-machining (working with several tools on the same geometry)

- Manual processing sequence management

- 2D simulation

- Creation of partial programs

3) ASPAN SE can also be equipped with the following optional modules:

- Commands for creating 3D elements (inclined plane, tilted hole / arc line)

- Nesting (single / multiple panels, parts list, graphical reports)

- Label creation / printing tools (operator configurable)

- 2D Vectorializer (bitmap conversion to vector)

- Artistic CAM 3D (convert bitmap to grayscale in 3D)

- Door fabrication management (parametric door realization)

- Manufacturing management of cabinets (parametric realization of cabinets and shelves) ASPAN SE can be upgraded to the full version of ASPAN PROSPECT at any time.

DRILLING UNIT 6V + 4H

Drilling machine with 10 independent spindles consisting of:

6 vertical spindles and 2 pairs of horizontal spindles (04 fully horizontal spindles).

The vertical spindles are positioned 32 mm apart between their centers along the X and Y axes; can be rotated clockwise and counterclockwise.

The basic position of the horizontal spindles, each pair has the possibility of right and left rotation,

it is mounted 55 mm from the center of the axis of the trolley in which they are mounted.

TELESERVISION

This allows immediate and direct access to the machine for numerical control via the Internet. (RJ45 port or wireless access). In this way, it is possible to check machine data, user programs, system variables I / O and install software updates, which guarantees:

- real-time responses

- quick problem solving

- reduction of machine downtime

- real-time software updates