TK 429P - Tekna 3-Axis CNC Vertical Machining Center. Specially designed for the processing of sectional panels, equipped with a clamping system that can be quickly adjusted to the width of the panel loaded. This enables panels of different widths to be processed without changing the machine tooling. It has a fixed and movable crossbar that can be moved along the Y axis and performs a pressing operation by a pneumatic piston. TK 429P is designed for drilling and milling in aluminum and steel plates for heavy industrial doors and garage doors and for sandwich panels with polyurethane foam core for walls and coatings etc. The standard version is 6600 mm long. Upon request, the machining center can be manufactured in various lengths to meet the specific needs of each customer. In order to simplify the machining process, TEKNA has developed software for the production of industrial and sectional doors that is capable of automatically creating machining programs. Design features: ...

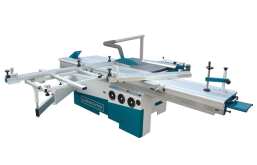

Wegoma FKS200 sliding table saw Sliding table saws FKS 200/280/320/380 The FKS200, FKS280, FKS320 and FKS380 high-performance sliding table saws. Manual height adjustment and side shift of the saw unit. Manual height adjustment and side shift of the scoring unit. Main engine power 4.0 kW or optionally 5.5 kW. Main saw blade 315 x 30 mm, scoring unit blade 120 x 20 mm. Double bearing sliding table 2000 x 405 mm (FKS200), 2800 x 405 mm (FKS280), 3200 x 405 mm (FKS320) 3800 x 405 mm (FKS380) Basic equipment: • The massive base and casing of the machine guarantee high stability and smooth running of the saw. • Large working table made of gray cast iron - extension and extension of the table included. • Gray reinforced cast iron saw unit - absolute accuracy and smooth running of the machine. Dual Guided Inclined Segments - Zero Point Swing. • Self-propelled scoring unit shifted horizontally and vertically - simple setting, prevents fraying of the cut s...

Wegoma S315 sliding table saw The S315 model, with extensive standard equipment, such as a serial scoring unit or a miter fence, is characterized by high power, precision and reliability as well as high quality at a very attractive price. Like all models of the S-series, the S315 is distinguished by its comfortable, quick and easy operation. Another advantage that allows you to save a lot of time in everyday work is the operation of the rip fence from the operator's position. The machine is equipped with a modern WEGOMA® sliding table (patent pending), the construction of which ensures not only durability but also the highest possible precision. Equipment: • Change the height, tilt and rip fence at the front of the machine with the hand crank. • Tilt angle and cutting width with digital display. • 4 kW main engine, 3 revolutions (3000, 4000, 5000 rpm) with belt adjustment, scoring unit with its own drive. • Angle stop up to 3.2 m in length, diagonal stop, stop flaps, mat...

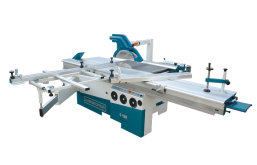

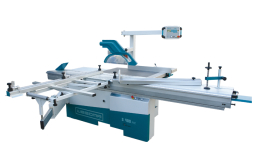

Wegoma S400 sliding table saw Our S400 has the same equipment as the S315, the difference is the adaptation to a saw blade with a maximum diameter of 400 mm, which increases the cutting capacity, and a 5.5 kW motor. Our airflow-optimized protective covers are attached to the hinged boom of the dust extractor. The lids automatically adjust to the thickness of the workpieces. The exchange between the wide and narrow lid is simple and requires just a few steps. The unnecessary cover can be attached to a specially designed holder. Equipment: • Change the height, tilt and rip fence at the front of the machine with the hand crank. Tilt angle and cutting width with digital display. • 4 kW main engine, 3 revolutions (3000, 4000, 5000 rpm) with belt adjustment, scoring unit with its own drive. • Angle limiter up to 3.2 m long, diagonal limiter, limiter flaps, material feeder, shelf for tools and manual quick-clamp included in the set. • Protective covers with dust extraction (nar...

WEGOMA S400NC sliding table saw Our S400NC saw in terms of construction and mechanics is the equivalent of the S400, the difference is the intelligent and modern electronic control system and the diagnosis function. It provides precision at the "press of a button". Comfortable control of cutting height, cutting angle, cutting width and electromotive adjustment of the scoring unit via the control panel. The control panel is mounted on a movable arm at the operator's eye level. The desired dimensions are read by means of precise magnetic tapes, which transmit the exactly read value to the display on the control panel. After switching the saw on, the electronically controlled scoring unit automatically rises to the set size, after switching it off, it returns to its starting position. During the construction of our modern control system, we paid special attention to simple and intuitive operation. As a result, the operation of the machine requires minimal operator training. Equipmen...

Rubber roller for the grinder set

A set of rubber rollers with a grinder spindle suitable for KS2250, KS2400, KS2600, KS2600FU Order no. Article 92000010 Spindle, rollers, adhesive abrasive rollers D = 30, 40, 50, 60 mm...

Rubber rollers for abrasive rollers suitable for:KS2250, KS2400, KS2580, KS2640FU, KS2700, KS2700FU, TB319, TB600, TB652, TB66, TB325Order no. Article92106671 Roller D = 30 mm92106681 Roller D = 40 mm92106691 Roller D = 50 mm92106701 Roller D = 60 mm...

Abrasive roller for WEGOMA grinders

Abrasive rollerLength: 150 mmØ=30 mm:Grain: 060 (No. 96014621), 080 (No. 96014631), 100 (No. 96014641), 120 (No. 96014640)Ø=40 mm:Grain: 060 (No. 96014651), 080 (No. 96014661), 100 (No. 96014671), 120 (No. 96014681)Ø=50 mm:Grain: 060 (No. 96014691), 080 (No. 96014701), No. 96014711 (100), 120 (No. 96014721)Ø=60 mm:Grain: 060 (No. 96014731), 080 (No. 96014741), 100 (No. 96014751), 120 (No. 96014761)...

Abrasive belt for grinders WEGOMA

Abrasive belt: Order no. ArticleAbrasive belt for KS2250 - height 150 mm96000006 150 x 2250 mm, grain 8096000007 150 x 2250 mm, grain 10096000008 150 x 2250 mm, grain 12096000024 150 x 2250 mm, grain 150Abrasive belt for KS2400 - height 150 mm96015261 150 x 2400 mm, grain 8096015281 150 x 2400 mm, grain 10096015291 150 x 2400 mm, grain 12096015301 150 x 2400 mm, grain 150Abrasive belt for KS2600, KS2600FU - height 150 mm96015216 150 x 2600 mm, grain 8096015217 150 x 2600 mm, grain 10096015218 150 x 2600 mm, grain 120TAbrasive belt for KS2600, KS2600FU - 2600 - height 200 mm96015313 200 x 2600 mm, grain 8096015323 200 x 2600 mm, grain 10096015333 200 x 2600 mm, grain 120Abrasive belt for KS2700, KS2700FU, TB 319 - height 150 mm96015361 150 x 2700 mm, grain 8096015371 150 x 2700 mm, grain 10096015381 150 x 2700 mm, grain 12096015391 150 x 2700 mm, grain 15096015401 150 x 2700 mm, grain 180...

Wegoma KS2250 grinding machine Solid wood sander with maintenance-free oscillation unit. Abrasive belt: 2250 x 150 mm. Standard equipment: • Maintenance-free oscillation unit. • Stable machine base - 500 x 300 mm. • 620 x 220 mm aluminum worktable, manual height adjustment. • Manually tiltable grinding unit in the range of 0 ° - 90 °. • Precise angular accuracy achieved by blocking the sanding unit. • Freely adjustable angular stop. • Connection of the dust extraction on the guard of the grinding unit, diameter - 100 mm. • Easy sanding belt change. • KS2250P - larger machine base 500 x 500 mm. • KS2250P - larger work table with pertinax 690 x 280 mm plate. Technical data: Voltage: 400V, 50/60 Hz Belt motor: 2.25 kW Engine revolutions: 3400 rpm. Belt speed: 20 m / sec. KS2250 table dimensions: 620 x 220 mm KS2250P table dimensions: 690 x 280 mm Belt dimensions: 2250 x 150 mm Machine dimensions: (L x W x H) 1250 x 550 x 1150 mm Weight ...

Wegoma KS2250P grinding machine Solid wood sander with maintenance-free oscillation unit. Abrasive belt: 2250 x 150 mm. Standard equipment: • Maintenance-free oscillation unit. • Stable machine base - 500 x 300 mm. • 620 x 220 mm aluminum worktable, manual height adjustment. • Manually tiltable grinding unit in the range of 0 ° - 90 °. • Precise angular accuracy achieved by blocking the sanding unit. • Freely adjustable angular stop. • Connection of the dust extraction on the guard of the grinding unit, diameter - 100 mm. • Easy sanding belt change. • KS2250P - larger machine base 500 x 500 mm. • KS2250P - larger work table with pertinax 690 x 280 mm plate. Technical data: Voltage: 400V, 50/60 Hz Belt motor: 2.25 kW E ngine revolutions: 3400 rpm. Belt speed: 20 m / sec. KS2250 table dimensions: 620 x 220 mm KS2250P table dimensions: 690 x 280 mm Belt dimensions: 2250 x 150 mm Machine dimensions: (L x W x H) 1250 x 550 x 1150 mm Weight...

Wegoma KS2400 grinder Robust and precise grinder with motorized oscillations Abrasive belt 2400 x 150 mm. Standard equipment: • Maintenance-free motorized oscillation unit. • Additional height-adjustable table for grinding the radii at the end of the abrasive belt with a spindle and additional abrasive rollers for external and internal shapes with diameters: 30, 40, 50 and 60 mm. • Abrasive Belt Assembly - Adjustable -10 ° - 90 ° easily and comfortably with handwheel. • Heavy steel base structure for stability and smooth operation (machine weight 260 kg). • Large, heavy cast iron work table with easy height adjustment based on a gas spring. Also moving back and forth towards the abrasive belt. • Precise angular accuracy achieved by blocking the sanding unit. • Large angular guide. • Dust extraction connection - 1x on the left side of the abrasive belt cover, 1x on the right side of the abrasive belt cover, 1x additional sanding table. • Stand for easy manual l...

Wegoma KS2600FU grinding machine Solid wood and veneer sanding machine - Robust and precise grinder with motorized oscillations - Easy sanding change from solid wood to veneer - Abrasive belt 2600 x 200 mm Standard equipment: • Veneer unit and stand for the feed unit. Easy sanding change from veneers to solid wood. • Large abrasive belt - 2600 x 200 mm. • Maintenance-free motorized oscillation unit. • Additional height-adjustable table for grinding the radii at the end of the abrasive belt with a spindle and additional abrasive rollers for external and internal shapes with diameters 30/40/50/60 mm. • Digital readout - for fine adjustment of the sanding unit tilt. • Precise angular accuracy achieved by blocking the sanding unit. • Heavy steel base structure for stability and smooth operation (machine weight 405 kg). • Large, heavy cast iron work table with easy height adjustment based on a gas spring. Also moving back and forth towards the abrasive belt. Table ...

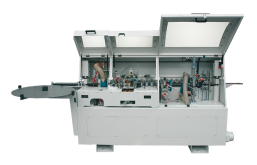

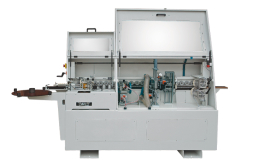

Edge banding machine WEGOMA KA100

Edge banding machine with glue tank KA100 • Automatic edgebander • Temperature control with standby and operation • Chain feeder adapted to heavy loads • Pressure unit with 3 individual adjustable rollers • Strong pneumatic double-sided trimming unit with guillotine • Combined group of milling and precise edge processing Technical data: Voltage: 400V, 50/60 Hz Power: 4.2 KW Revolutions: 12,000 rpm. Pressure: 6 bar Speed: 7 m / min Weight: 620 kg Min.Tape Thickness: 0.5 mm (Optimum 0.4 mm) Max. tape thickness (strip): 2 mm (Optimum 3 mm) Workpiece thickness: 12 - 40 mm Table for rolled up tapes: Ø 500 mm...

Edge banding machine WEGOMA KA100_2

Edge banding machine with glue tank KA100 / 2 / KA100 / 2-F • Automatic edgebander • Temperature control with standby and operation • Chain feeder adapted to heavy loads • Pressure unit with 3 individual adjustable rollers • Powerful PLC controlled double-sided trimming unit • Combined group of milling and precise edge processing • One dust extraction port • Optional surface treatment unit • KA100 / 2-F with pre-milling unit Technical data: Voltage: 400V, 50/60 Hz Power: 4.5 KW Revolutions: 12,000 rpm. Pressure: 6 bar Speed: 7 m / min Weight: 705 kg Min.Tape Thickness: 0.5 mm (Optimum 0.4 mm) Max. tape thickness (strip): 2 mm (Optimum 3 mm) Workpiece thickness: 12 - 40 mm Table for rolled up tapes: Ø 500 mm ...

Edge banding machine WEGOMA KA100_2F

Edge banding machine with glue tank KA100 / 2 / KA100 / 2-F • Automatic edgebander • Temperature control with standby and operation • Chain feeder adapted to heavy loads • Pressure unit with 3 individual adjustable rollers • Powerful PLC controlled double-sided trimming unit • Combined group of milling and precise edge processing • One dust extraction port • Optional surface treatment unit • KA100 / 2-F with pre-milling unit Technical data: Voltage: 400V, 50/60 Hz Power: 4.5 KW Revolutions: 12,000 rpm. Pressure: 6 bar Speed: 7 m / min Weight: 705 kg Min.Tape Thickness: 0.5 mm (Optimum 0.4 mm) Max. tape thickness (strip): 2 mm (Optimum 3 mm) Workpiece thickness: 12 - 40 mm Table for rolled up tapes: Ø 500 mm ...

Edge banding machine WEGOMA KA100_3

Edge banding machine with glue tank KA100 / 3 / KA100 / 3-F • Automatic edgebander • Temperature control with standby and operation • Chain feeder adapted to heavy loads • Pressure unit with 3 individual adjustable rollers • Powerful PLC controlled double-sided trimming unit • Combined group of milling and precise edge processing • One dust extraction port • Optional surface treatment unit • Optional corner processing unit • Optional polishing unit • KA100 / 3-F with pre-milling unit Technical data: Voltage: 400V, 50/60 Hz Power: 5 KW Revolutions: 12,000 rpm. Pressure: 6 bar Speed: 7 m / min Weight: 807 kg Min.Tape Thickness: 0.5 mm (Optimum 0.4 mm) Max. tape thickness (strip): 2 mm (Optimum 3 mm) Workpiece thickness: 12 - 40 mm Table for rolled up tapes: Ø 500 mm ...

Edge banding machine WEGOMA KA100_3F

Edge banding machine with glue tank KA100 / 3 / KA100 / 3-F • Automatic edgebander • Temperature control with standby and operation • Chain feeder adapted to heavy loads • Pressure unit with 3 individual adjustable rollers • Powerful PLC controlled double-sided trimming unit • Combined group of milling and precise edge processing • One dust extraction port • Optional surface treatment unit • Optional corner processing unit • Optional polishing unit • KA100 / 3-F with pre-milling unit Technical data: Voltage: 400V, 50/60 Hz Power: 5 KW Revolutions: 12,000 rpm. Pressure: 6 bar Speed: 7 m / min Weight: 807 kg Min.Tape Thickness: 0.5 mm (Optimum 0.4 mm) Max. tape thickness (strip): 2 mm (Optimum 3 mm) Workpiece thickness: 12 - 40 mm Table for rolled up tapes: Ø 500 mm...

Feeder WEGOMA Specjal VS18_180

Feeder WEGOMA Specjal VS18_180 VS18 / 180 copy feeder - Feeder for copying used for table saws, milling machines and edgebanders - Used for: round parts, oval table tops, chairs, arches etc. - Strong draft, suitable for serial production thanks to its stable structure. Technical data VS18 / 180 Voltage: 400V, 50/60 Hz Power: 0.37 KW Roller width: 40 mm Roller diameter: Ø 180 mm Number of Axes: 1 Max. passage height: 220 mm Feed speed VS18 / 180: 2.2 / 2.9 / 4.4 / 5.8 / 7.4 / 9.8 / 14.8 / 19.7 m / min Weight: 54 kg ...

Feeder WEGOMA Specjal VS24 Feeder for VS24 saws with a standard stand Special feed device for table saws Can be purchased with a standard or comfortable tripod. Technical data: Voltage: 400V, 50/60 Hz Power: 0.37 kW Number of axles: 2 Max. passage height: 220 mm Roller diameter: 180x20 mm Number of rolls: 3 Feed speed right / left: 4-8-11-22 m / min Additional gear set: 8-16-22-44 m / min Weight VS24 / VS24S: 69/82 kg ...