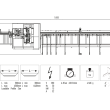

Cutting and machining center SUPER CUT 231

- Add feedback:

- Availability: Exists (1 szt.)

SUPER CUT 231 cutting and milling center

- Compatible with all types of PVC profiles and optimization programs.

- The center has a 3-axis CNC machining unit controlled by servomotors, which allows you to perform all operations, such as milling, drilling, marking, drilling a

- hole for the handle on four surfaces of the profile, while maintaining the set parameters.

- The milling unit mills the holes for the handle and cylinder in one operation, ensuring minimal machining time.

- The triple drilling process of the hole for the handle, performed in one motion, ensures minimum machining time.

Use the form below to ask about the price and product details

SUPER CUT 231 cutting and milling center

- Compatible with all types of PVC profiles and optimization programs.

- The center has a 3-axis CNC machining unit controlled by servomotors, which allows you to perform all operations, such as milling, drilling, marking, drilling a

- hole for the handle on four surfaces of the profile, while maintaining the set parameters.

- The milling unit mills the holes for the handle and cylinder in one operation, ensuring minimal machining time.

- The triple drilling process of the hole for the handle, performed in one motion, ensures minimum machining time.

- Possibility of obtaining high productivity by simultaneously performing cutting and milling operations.

- Minimizes machining time by milling the door lock and espagnolette channel in one operation.

- Losses during profile loading are minimized thanks to the independent movement of the robot arm holder and the profile loading station.

- The profile gripper has the ability to move in 3 axes, which speeds up the change between profiles.

- Automatic profile capture system.

- Automatic profile length detection function.

- The profile feeder can be loaded with profiles of the desired length in the range of 500 mm - 6500 mm.

- Support for remote connections.

- 15.6" High Performance Touch Screen Industrial PC Controlled by Austrian B&R

- 10 high-speed special air-cooled spindles.

- The servo-controlled cutting unit ensures cutting precision of 0.1⁰ in the range of 30⁰-150⁰.

- Transportation of waste to the warehouse using an automatic conveyor system.

- Servomotor system for quick unloading of profiles after cutting.

- Up and down saw servo control system for fast cutting.