BDM ULTIMA STAL

- Add feedback:

- Availability: Exists (1 szt.)

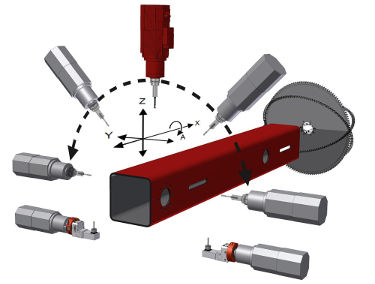

Cutting and machining center for steel profiles BDM ULTIMA STAL

Use the form below to ask about the price and product details

Cutting and machining center for steel profiles BDM ULTIMA STAL

Application:

• A proposal for small and medium-sized enterprises working on steel profiles, who want to automate their production process in the field of comprehensive machining and cutting.

• Processing and cutting of steel profiles for structural elements such as: windows, doors, balustrades, light industrial structures.

Profile dimensions:

• 7,500 mm (L) / 150 mm (H) / 100 mm (W)

• Maximum wall thickness - 5 mm

Characteristic:

• The center consists of a 4-axis mobile machining center and a stationary cutting unit;

• Network ready, IPC controlled;

• Full automation of production from the processing stage to the stage of cutting the barbell into sections of the selected length;

• Working time savings up to 70%;

• 3 functional modes of use:

1) as a production line;

2) machining center;

3) standalone cutting unit;

• Versatile profile processing on 4 sides;

• Numerically controlled, automatic barbell setting;

• Automatic tool magazine for up to 12 tools;

• The cutting unit is equipped with a servo-operated blade with a smooth adjustment range between 30 ° - 150 ° and automatic side and vertical clamps;

• Blade with a diameter of 500 mm;

• a rivet assembly station for fixing the glazing bead is possible as an additional option;

• The operator manages the machine functions using the Uni-link "Onboard" software.

• The modular nature of the machine enables the introduction of customized solutions and the extension of functionality

Ultima cutting module

Ultima machining module