ALBZ-100/100L

- Add feedback:

- Availability: Exists (1 szt.)

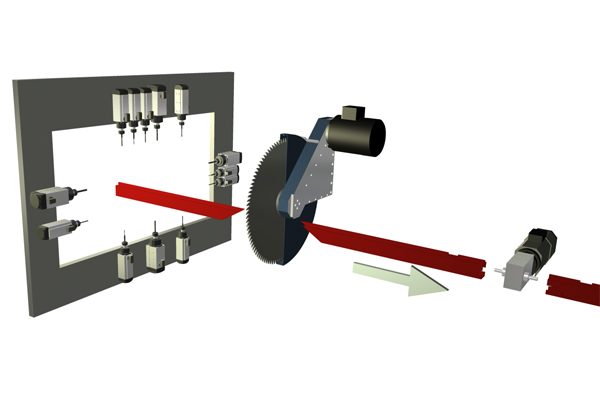

ALBZ-100 / 100L - aluminum machining and cutting center

Use the form below to ask about the price and product details

ALBZ-100 / 100L - aluminum machining and cutting center

Application:

• Fully automated center for processing and cutting aluminum profiles, intended for use in areas such as: structural elements, curtain walls, kitchens, furniture, industrial components.

Profile dimensions:

• 300 mm long / 250 mm high / 7500 mm wide

Characteristic:

• Loading warehouse with one-time capacity for up to 12 profiles;

• Loading and positioning of the profile in the machining station by means of a servo-operated gripper integrated with the roller conveyor (speed 120 m / min);

• Automatically adjusted, consisting of two independently adjustable supports, the base for virtually any type of profile, ensuring its 100% stability during processing;

• Versatile profile processing on all 4 sides, including profile end-face processing;

• 14 processing tools are placed on a servo-operated frame, including the profile on 4 sides;

• Remarkable performance achieved thanks to a short machining cycle;

• Cutting station, equipped with a blade with a diameter of 750 mm and a servo-operated, smoothly adjustable, inclination in the range of 45 ° / 135 °

• Cutting speed: 80m / s • Mechanized unloading by means of a gripper and a roller conveyor;

• The drive of the machining module along the x, y, z axes is provided by servo-controlled ball screws;

• Automatic position correction thanks to the measurement of the height and width (optional) of the profile;

• Bekhoff control unit with TwinCat software and TFT touch screen, also suitable for network control and remote technical support

• The modular nature of the machine enables the introduction of customized solutions and the extension of functionality